Pic. 1. 3D-model of Korean SMT Solutions booth at preparation to Productronica 2013 show.

Pic. 2. Service engineers of Korean SMT Solutions company start up the technological equipment line at the booth.

Pic. 3. Implemented project of Korean SMT Solutions booth at Productronica 2013 show.

Dear ladies and gentlemen, we hope you could visit Korean SMT Solutions booth at Productronica 2013 international show in Germany. It is importance experience for our company since here Korean SMT Solutions had been presented for the European electronics manufacturers for the first time. Equipment of leading vendors from South Korea was shown within technological line, and production of souvenir digital clocks was launched straight in the booth.More than 500 of such souvenirs were produced.

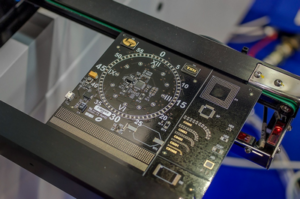

Pic. 4. Souvenir digital clock assembled at Korean SMT Solutions booth.

The main goal of Korean SMT Solutions is popularization of South Korean equipment in Europe. For this purpose, such vendors as Mirae, Mirtec, SJ InnoTech, and TSM had united the efforts for supplying the European electronics manufacturers with technological equipment.

Pic. 5. Main entrance to Productronica international trade show (Munich, Germany).

Korean SMT Solutions (KSS) is the complete solutions for European electronics manufacturers based on technological equipment from the best South Korean vendors.Korean SMT Solutions works with European distributors supplying such equipment.The main goal of Korean SMT Solutions is to provide the highly professional informational and technical support at equipment selection and high-quality service support.KSS specialists will design a detailed project of a technological line according to customer’s requirements.

A warehouse located in European Union is constantly supplied with equipment and spare parts.That allows quick supplying of equipment and eliminating of emerging failures.Similar work system is alreadу functioning in Russia making KSS equipment one of the most popular in this country.Official representative of Korean SMT Solutions is Russia – LionTech company.

Pic. 6. Leading vendors of South Korea as parts of Korean SMT Solutions.

In the conditions of frequently changing demands of the current market, the manufacturers would like to have a flexible production for timely manufacturing of product and for quality control to correspond all the up-to-date requirements. According to current tendency towards downsizing of components and, as a consequence, to lessening of pad size, it becomes necessary to control the quality of assembled product on all the stages. Korean SMT Solutions understands it and offers a solution for the companies both producing different products in high mix and bearing responsibility for quality of its products.

Pic. 7.High performance flexible line with online quality control on all the assembly stages.

To demonstrate such solutions, a high-performance flexible line with online quality control on all the assembly stages was presented at the show. This solution uses three quality control systems, one after each process step:

- MS11 system of solder paste application 3D control after HP520 stencil printer;

- MV7 system of optic control for component placement after two systems of SMD components placement;

- MV7 system of soldering quality control (possible to change into revolutionary MV9 system);

- Data processing terminal from all the IntelliTracker control systems.

The line included pick-and-place systems for SMD components of new MR series from Mirae company. At first sight, they do not differ much from MX series. In fact, nearly all the functional parts were changed. New systems received more flexible structure and more powerful, more precise, and more reliable mechanics. More detailed description will be published in the nearest future. Official sales will start early 2014.

Lots of European customers have got acquainted with functioning of MIRTEC equipment in real-time production mode at Korean SMT Solutions booth. Most of them were admired and admitted they had understood the role of inspection only after seeing it in action. However, the Mirtec company booth has attracted attention with demonstration of high-precision quality control system including advantages both 2D and 3D technologies for tracing the most complex defects.

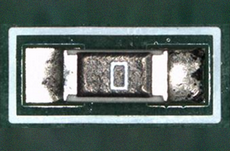

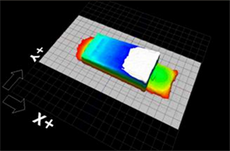

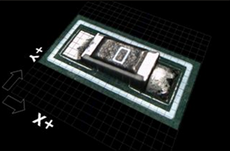

AOI MIRTEC MV-9 is equipped with central camera 15 Mpix with telecentric lens, 4 side view cameras 10 Mpix, multi-level lighting system, and 3D subsystem.Pic. 9 shows the image of a chip created by 2D/3D technology used in AOI MIRTEC MV-9 system. Pay attention to exceptional details and clearness of the image to get a complete idea on availability of chip defect.

All this equipment is not new on European market; more than 300 enterprises in Europe are equipped with it.And now we are getting closer to Europe and trying to give better access to equipment for our customers providing more possibilities and guaranties.

To get detailed consultations on complete solutions presented in the booth and to apply for the servicing, just send and email via mail@korean-smt.com, and our agent in your area will contact you. Please pay attention that it is possible to get acquainted with all the equipment in real-time production mode.

Pic. 8. AOI MIRTEC MV-9 system with 2D and 3D technology of image processing.

Pic. 9. 2D/3D processing of lifted component image. a) 2D image from camera 15 Mpix

Pic. 9. 2D/3D processing of lifted component image. b) 3D image

Pic. 9. 2D/3D processing of lifted component image. c) combination of 2D/3D images

Korean SMT Solutions is the insurance of your success!